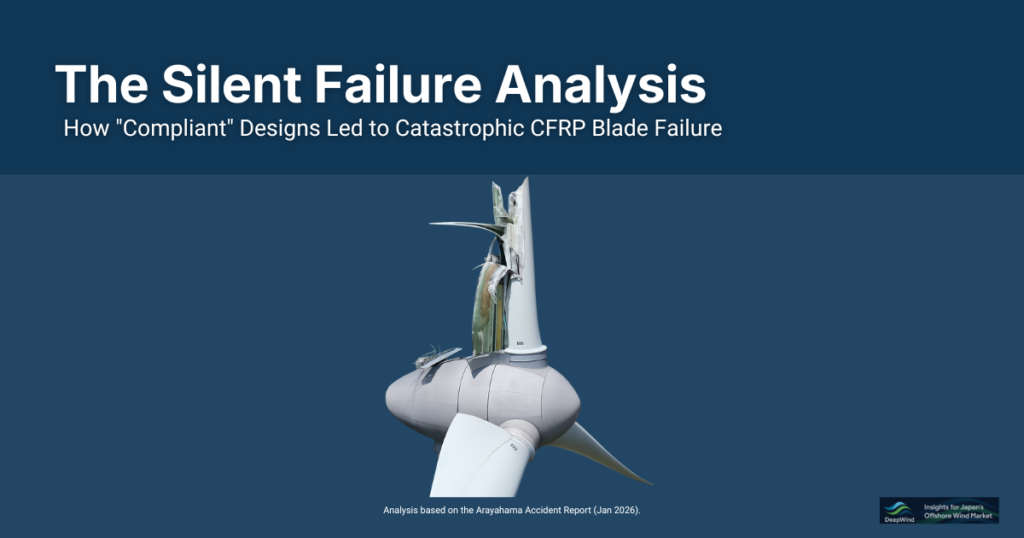

Introduction: The Mystery of a Calm Day Collapse

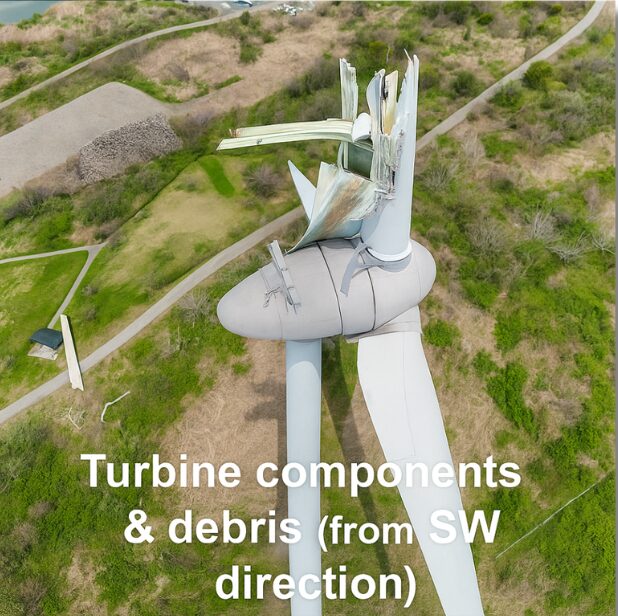

On May 2, 2025, a massive blade fracture occurred at the Arayahama Wind Power Station in Akita, Japan. The SCADA data showed wind speeds of 18.9 m/s—well within design limits—and critically, no lightning was recorded on the day of the incident.

How could a certified turbine suffer such a catastrophic structural failure without an external trigger? The detailed investigation report, released in January 2026, reveals a complex failure mechanism specific to Carbon Fiber Reinforced Plastic (CFRP) blades, acting as a “ticking time bomb” hidden within the structure.

This article takes a deep dive into this specific topic, but if you’re looking for a comprehensive overview of offshore wind technologies, check out our full summary article here:

👉 Offshore Wind Technology 2025: Foundations, Floating Wind, Turbines, and Innovations

1. The Mechanism: The 600kV “Spark Gap”

The Fatal Flaw in Design

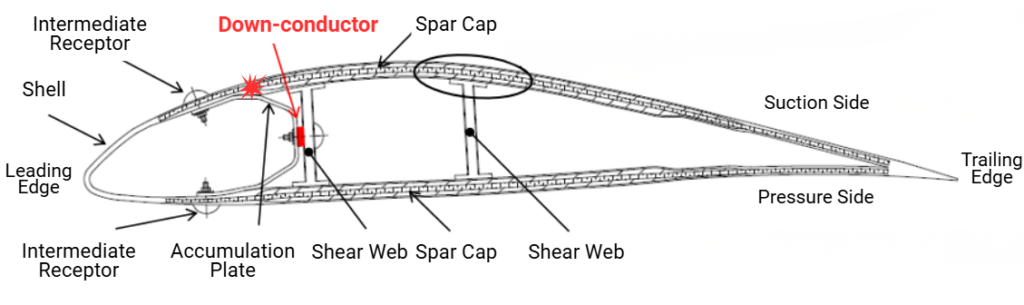

The turbine in question, an Enercon E-82 commissioned in 2010, utilized CFRP for its main structural spar caps. The root cause lies in a specific design choice: the conductive CFRP spar cap was not electrically bonded to the lightning protection system (down-conductor). While compliant with IEC standards at the time (2010), this created a dangerous potential difference.

Simulation Data Reveals the Scale

Post-accident simulations revealed shocking figures. When a standard lightning current (100kA) flows through the down-conductor, the potential difference between the conductor and the non-bonded CFRP layer reaches:

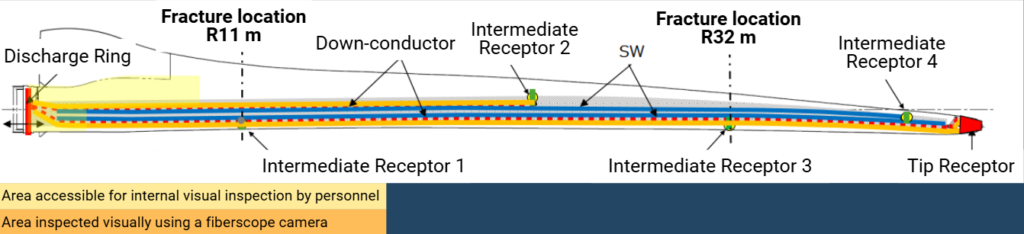

• ~400 kV at 11 meters from the root (R11m)

• ~600 kV at 32 meters from the root (R32m)

Even more concerning, analysis showed that insulation breakdown (arcing) could occur with currents as low as 0.1kA. This means that even minor lightning activity over the years caused repeated internal sparking, carbonizing the resin and initiating delamination.

2. The Timeline: A Retrofit That Came Too Late

The failure was not an isolated event but the result of a race against time that the industry lost.

• 2010 (Commissioning): The design complied with the IEC standards of the time.

• 2016-17 (Global Incidents): Following similar blade failures in Portugal, the manufacturer recognized the risk and developed a retrofit plan to remove high-risk components (intermediate receptors).

• 2017 (Inspection): Internal damage (spark tracks) was already present at R11m, but it was missed because it was outside the standard inspection scope.

• 2020 (The Retrofit): The retrofit was applied to the Arayahama turbine, removing the sparking metal components.

However, the damage had already been done. The internal delamination initiated in 2017 continued to propagate due to mechanical fatigue loads during operation. Even after the “spark” source was removed in 2020, the weakened CFRP structure eventually succumbed to fatigue in 2025.

3. The Blind Spot in O&M

Why was this progressive damage never flagged? The incident highlights a critical gap in standard maintenance protocols.

1. The “Hard-to-Access” Excuse: The critical failure point (R11m) was located in an area considered “hard-to-access” for human inspectors. Standard guidelines did not mandate detailed internal checks in this specific zone.

2. Information Asymmetry: The manufacturer had noted discharge marks in previous years but deemed them “non-critical” and did not fully communicate the risk to the local O&M provider. Lacking specific expertise in CFRP failure modes, the O&M provider accepted the “no repair needed” assessment.

4. Regulatory Shift: METI’s Response

In response to this failure, Japan’s Ministry of Economy, Trade and Industry (METI) is moving to tighten regulations to prevent recurrence.

Expanded Inspection Scope

METI is revising the interpretation of “Periodic Self-Inspection” rules. The new mandate is expected to require inspections of all internal areas surrounding down-conductors, regardless of accessibility. This effectively mandates the use of drones or robotic crawlers for internal blade inspections.

Clarifying Technical Standards

New guidelines will strictly define safety requirements for blades where internal structural components (like CFRP) are not electrically bonded to the lightning protection system.

5. Conclusion & Industry Takeaways

The Arayahama incident serves as a critical case study for the wind industry as early-generation CFRP blades age. For asset managers operating similar non-bonded CFRP blades, the report recommends immediate actions:

• Upgrade Monitoring: Install lightning detection systems capable of monitoring di/dt (current rate of change), a key predictor of insulation breakdown potential.

• Implement NDT: Move beyond visual inspections. Ultrasound or thermographic testing is essential to detect the invisible internal delamination that brought down the Arayahama turbine.

Compliance with past standards is no guarantee of future safety. The industry must shift towards risk-based management tailored to the specific material properties of CFRP.

References

- Sakura Wind Power / Hitachi Power Solutions, “Report on Blade Failure at Arayahama Wind Power Station” [Japanese]

- METI, “Regarding the Blade Failure Accident at Arayahama Wind Power Station” [Japanese]

For a broader look at offshore wind technologies and future innovations, make sure to explore our comprehensive summary article:

🌊 Offshore Wind Technology 2025: Foundations, Floating Wind, Turbines, and Innovations

Japan’s offshore wind is no longer constrained by ambition — but by viability.📘 DeepWind Premium Report

A decision-oriented report synthesizing commercial viability, cost/revenue misalignment, supply-chain constraints, and Round 4 implications.

View the report (Gumroad)

- 🔍Market Insights – Understand the latest trends and key topics in Japan’s offshore wind market

- 🏛️Policy & Regulations – Explore Japan’s legal frameworks, auction systems, and designated promotion zones.

- 🌊Projects – Get an overview of offshore wind projects across Japan’s coastal regions.

- 🛠️Technology & Innovation – Discover the latest technologies and innovations shaping Japan’s offshore wind sector.

- 💡Cost Analysis – Dive into Japan-specific LCOE insights and offshore wind cost structures.