Introduction

Wind power is a renewable energy technology that converts the kinetic energy of wind into electricity. Offshore wind, in particular, is gaining attention as a core energy source due to its more stable wind conditions compared to onshore, allowing for consistent generation even at night.

The Japanese government has set a target of achieving net-zero greenhouse gas emissions by 2050 and aims to expand offshore wind capacity to 45GW by 2040, equivalent to around 45 nuclear reactors. Offshore wind, leveraging Japan’s vast maritime potential, plays a key role in enhancing energy security and revitalizing local economies.

This article takes a deep dive into this specific topic, but if you’re looking for a comprehensive overview of offshore wind technologies, check out our full summary article here:

👉 Offshore Wind Technology 2025: Foundations, Floating Wind, Turbines, and Innovations

1. Basic Principles of Wind Power and Energy Conversion

- Conversion Process: Wind rotates the blades, and this motion is transmitted through the main shaft and gearbox (or directly via direct drive) to the generator.

- Betz’s Law: The theoretical maximum efficiency of converting wind energy is 59.3%. Real-world systems approach this limit through technologies like variable pitch and yaw control.

- Cubic Wind Speed Relationship: Power output is proportional to the cube of wind speed. Doubling the wind speed results in about eight times more electricity, making site selection critical.

2. Key Components of a Wind Turbine

- Rotor (Blades + Hub): Made of FRP (fiber-reinforced plastic); three-blade design is standard. Includes pitch control for efficiency and protection.

- Nacelle Components:

- Main Shaft & Bearings: Forged from high-strength steel

- Gearbox: Increases rotation speed for generation; direct-drive systems are growing

- Generator: Includes induction, synchronous, and permanent magnet types, with variable speed control

- Tower & Foundation:

- Cylindrical steel tower: Height of 80-140m, weighing several hundred tons

- Foundation Types:

- Fixed-bottom: Includes pedestal, footing, and pile foundations

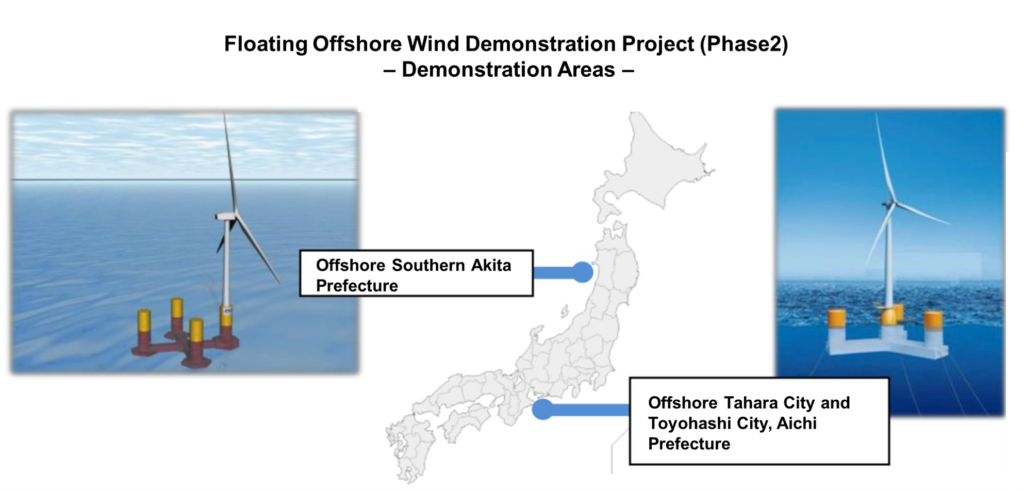

- Floating: Barge, semi-submersible, spar, and TLP types for deep water

- Control Systems:

- Yaw control: Aligns turbine with wind direction

- Pitch control: Optimizes output and safety by adjusting blade angles

3. Types and Characteristics of Wind Power

| Classification | Type | Advantages | Disadvantages |

|---|---|---|---|

| Axis | Horizontal-axis (HAWT) | High efficiency, scalable | Noisy, requires yaw mechanism |

| Vertical-axis (VAWT) | Quiet, wind-direction independent | Low efficiency, limited scalability | |

| Location | Onshore | Lower construction cost, easy transport | Site constraints, variable wind |

| Offshore | Stable wind, large turbines, minimal noise impact | High cost, submarine cables needed | |

| Floating Type | Barge | Simple, low cost | Prone to motion, wave limits |

| Semi-sub | Stable, easy to install | Heavy, costly | |

| Spar | Highly stable, offshore suited | Deepwater only, hard to install | |

| TLP | Low motion, lightweight | Expensive mooring, not commercial yet |

4. Factors Affecting Power Efficiency

- Wind Speed/Conditions: Stable offshore winds yield higher generation due to the cubic relationship

- Installation Environment: Factors like distance from shore, water depth, turbulence, and terrain affect performance

- Turbine Design: Blade length/shape, hub height, variable pitch systems, and new technologies enhance profitability

- Environmental Constraints: Turbine placement and operational pauses may be required to protect birds and marine life

5. Grid Connection and Power Management

- Connection Process: Pre-consultation → Application → Technical review → Contract → Construction → Grid connection

- Over 10,000 kW requires approval by the Organization for Cross-regional Coordination of Transmission Operators (OCCTO)

- Grid Operation and Stabilization:

- Smart Grids: Balance supply/demand, enable demand response, rapid recovery from outages

- Frequency & Voltage Control: Battery storage, TSC/SSC systems

- Transmission Loss Reduction:

- Extra-high voltage (275kV/500kV) to minimize losses

- HVDC: ~3% loss over 1000 km

- Superconducting cables: Promising for future if cooling costs fall

6. Safety Measures and Environmental Considerations

- Lightning Protection: Receptors, lightning rods, direct strike sensors, auto shutdown and inspection protocols

- Noise Control: Use of vibration dampers, sound-absorbing materials, tuned mass dampers

- Bird Protection: Site selection to avoid migratory paths, radar-based turbine shutdown, monitoring

- Landscape and Ecosystems: Offshore installation reduces visual impact; coexistence with fisheries and shipping required

Conclusion

Offshore wind power is a “system of systems” that combines optimized engineering and marine conditions to achieve large-scale renewable generation. Floating wind holds great promise for Japan’s deep waters but must overcome cost and technical barriers.

Future development will hinge on integration with battery storage and hydrogen, supply chain strengthening, regulatory reform, and international cooperation. Offshore wind will remain a vital pillar in Japan’s path to carbon neutrality by 2050.

For a broader look at offshore wind technologies and future innovations, make sure to explore our comprehensive summary article:

🌊 Offshore Wind Technology 2025: Foundations, Floating Wind, Turbines, and Innovations

Japan’s offshore wind is no longer constrained by ambition — but by viability.📘 DeepWind Premium Report

A decision-oriented report synthesizing commercial viability, cost/revenue misalignment, supply-chain constraints, and Round 4 implications.

View the report (Gumroad)

- 🔍Market Insights – Understand the latest trends and key topics in Japan’s offshore wind market

- 🏛️Policy & Regulations – Explore Japan’s legal frameworks, auction systems, and designated promotion zones.

- 🌊Projects – Get an overview of offshore wind projects across Japan’s coastal regions.

- 🛠️Technology & Innovation – Discover the latest technologies and innovations shaping Japan’s offshore wind sector.

- 💡Cost Analysis – Dive into Japan-specific LCOE insights and offshore wind cost structures.